A new horizon

Recovering copper and other critical minerals from mining waste

About Us

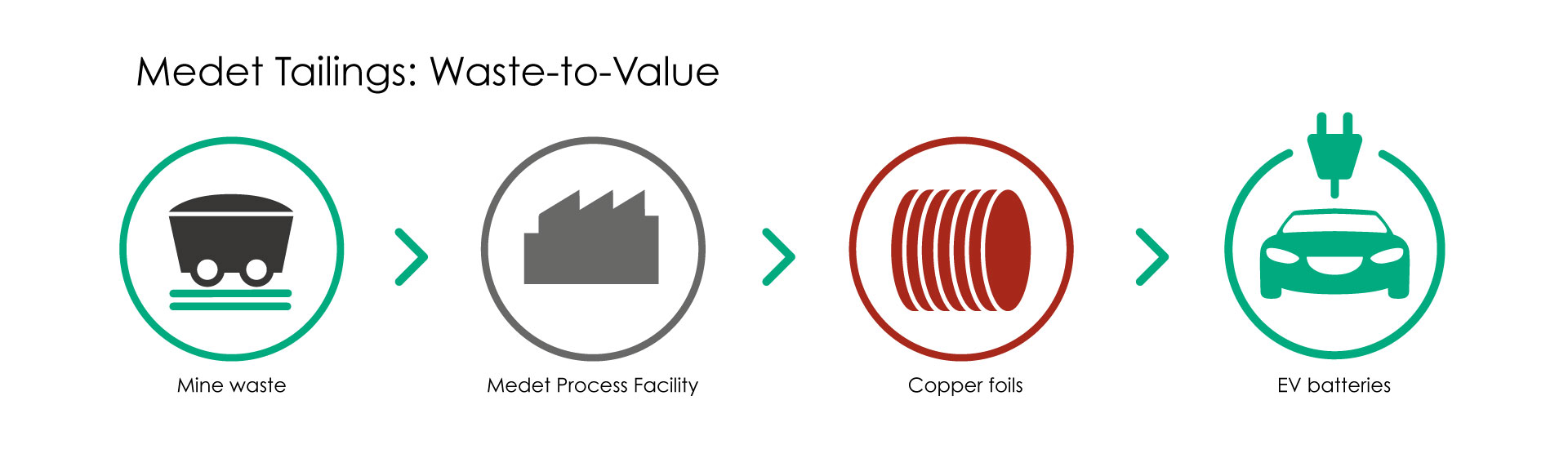

ReOre Technologies is currently developing the Medet Tailings project; an innovative clean technology project focused on developing a sustainable European supply chain for copper and other critical raw materials from the recycling of historic mine tailings, transforming what was once considered waste into a critical resource for the energy transition.

By recovering copper from the recycling of mine tailings at the Medet site, the project aims to contribute to the EU’s goals of strengthening the European supply chain for critical raw materials and improving circularity and sustainability.

In addition, the project will have positive environmental benefits for the site and surrounding areas, through the remediation of environmental damage caused from historical mining at the location and reinstatement of the original valley.

The Project

Located in central Bulgaria, the Medet tailings deposit is the largest resource of copper (Cu) tailings in Eastern Europe.

The 2,200-hectare site contains approximately 110 million metric tonnes (Mt) of waste (tailings) material, from the mining of copper-molybdenum porphyry deposits.

In addition to the tailings deposit, the site also includes existing infrastructure for the purpose of reprocessing the waste material.

The site is owned and operated by MBS EAD, a subsidiary of Altilium Metals Ltd, a UK-based clean technology group supporting the transformation of the global energy sector from fossil-based to zero-carbon.

Understanding where tailings come from is the first step in unlocking what they still contain

Tailings are generated during the mineral processing stage of mining, after ore has been extracted from the ground, crushed, ground, and treated to recover valuable metals.

During processing, only a fraction of the ore becomes final product. The remaining finely ground minerals, along with process water and residual reagents, form tailings. These materials are regularly transported as a slurry and deposited into engineered containment facilities designed for long-term storage and environmental control.

Understanding how tailings are produced is critical to understanding their potential. Tailings are not raw waste, but processed materials that have already undergone comminution. This creates opportunities for reprocessing using modern, environmentally compatible technologies.

At ReOre Technologies, we focus on this intersection between processing history and future opportunity. Our EcoMineral technology recovers copper from mine tailings and challenging minerals, generating additional value from what has already been mined.

Latest news

Read our latest announcements and recent media coverage.

Get in touch

To find out more about this project, please contact us at info@reore.tech

ReOre Technologies is part of Altilium.